POLYTEC-EMC specialises in casting machines using low pressure mixing technology. Whilst our customers mainly use these machines for casting polyurethane elastomers, they are also suitable for dispensing products such as epoxy resins, glues, sealants, silicones, RIM systems and other types of liquid and paste like media.

The machines are made to order to your exact requirements, and can be used to process all prepolymer types, as well as various curatives including MOCA and Ethacure. Heating is available up to 130oC (266oF).

2 Component machines

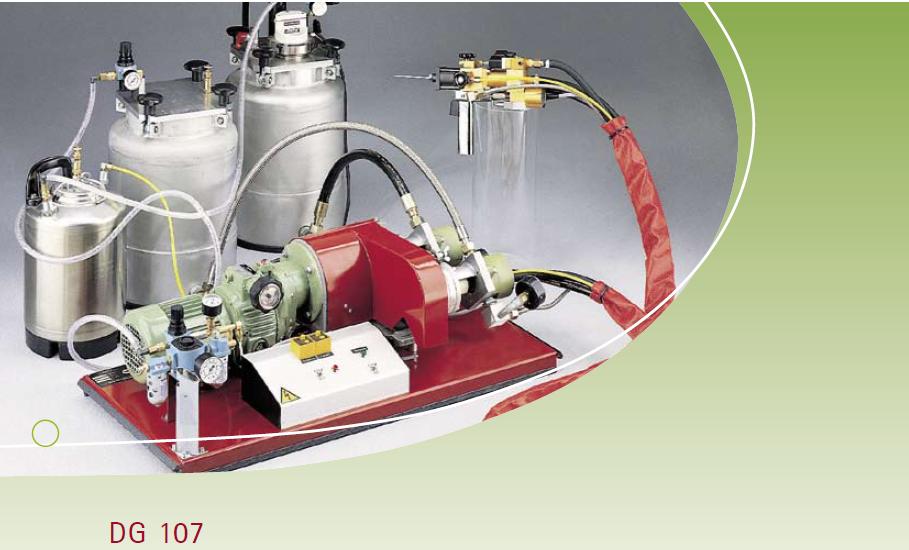

The types available are the DG-10, DG-105, DG-107 and DG-108.

These lower cost machines are suitable for small to medium production outputs.

3 Component machines

The type available is the DG-103.

This is designed for industrial use in manual, semi-automatic or fully computerized applications, utilizing the programmable on-board PLC. The modular construction allows all conventional 2 and 3 component polyurethanes to be cast.

The flow rate can reach up to 15kg/min (33lb/min).

Multi Component Equipment

DG-153

The latest development from Polytec EMC is the DG-150 series machine. This is available for hot and cold castable materials, in 2 or 3 component set up. The machine comes standardized with outputs of 6, 12 or 18kg/min, with tank capacities of 60L to 300L. Options include colour dosing units and vacuum pump.

DG-200

This is the professional solution with the ability to process up to 6 components at flowrates up to 100kg/min. The component tanks are sized to order, and mix ratio control is monitored by on-board mass flow control systems.

Automation

Based on nearly 30 years of experience, Polytec EMC also supplies peripheral and special purpose equipment for low pressure dispensing machines. For example heated casting tables, ovens, material processing plants, robots and handling solutions.